mil 810f pdf

MIL-STD-810F PDF: A Comprehensive Overview

MIL-STD-810F is a U․S․ Department of Defense test method standard, ensuring technology durability; accessing its PDF documentation requires navigating official sources or exploring third-party summaries․

What is MIL-STD-810F?

MIL-STD-810F represents a United States military standard, a rigorous set of test methods designed to assess the durability and reliability of equipment․ It doesn’t certify a product itself, but rather outlines how equipment is tested against a variety of environmental stressors․ These tests simulate conditions a product might encounter in real-world military applications, including temperature extremes, humidity, shock, vibration, and more․

The standard aims to ensure equipment can withstand harsh conditions and continue functioning as intended․ It’s important to understand that manufacturers choose which tests to perform based on the intended use of their product, and compliance is often self-certified; The “F” designation indicates a specific revision of the standard, adopted in the year 2000, though later revisions exist․

Historical Context and Revision Dates

The MIL-STD-810 standard has a long history, evolving over decades to reflect advancements in technology and changing military needs․ Originally established in 1962, it underwent numerous revisions․ MIL-STD-810F, specifically, was approved and released in 2000, representing a significant update to previous versions․

Prior to “F”, there were iterations like 810A, 810B, 810C, 810D, and 810E, each building upon the last with refined test procedures and expanded environmental factors․ Following 810F, the standard transitioned to 810G in 2008, and then to 810H, the current version, in 2019․ Each revision isn’t a complete overhaul, but rather an update to reflect current engineering practices and address emerging threats to equipment reliability․

The Purpose of the MIL-STD-810F Standard

The core purpose of MIL-STD-810F is to establish a uniform set of test methods for evaluating the durability and reliability of equipment intended for military applications․ It doesn’t certify products themselves, but rather outlines how to test them against a range of harsh environmental conditions․

These conditions include, but aren’t limited to, temperature extremes, humidity, shock, vibration, and dust․ By subjecting equipment to these tests, the standard aims to predict its lifespan and performance in real-world operational scenarios․ This ensures that military personnel have access to dependable technology, even in demanding environments․ The standard also assists designers in creating more robust and resilient products․

Key Differences Between MIL-STD-810F and Later Versions

While MIL-STD-810F was a significant benchmark, subsequent revisions – notably MIL-STD-810G and MIL-STD-810H – introduced crucial updates․ Later versions shifted from prescriptive test procedures to a more tailored, performance-based approach․ This means newer standards emphasize defining the specific environmental conditions a product will encounter, rather than rigidly adhering to standardized tests․

MIL-STD-810G added more emphasis on human factors and expanded testing for cybersecurity threats․ MIL-STD-810H, the current version, further refined the process, improving clarity and reducing ambiguity․ Although products may claim compliance with MIL-STD-810F, understanding these evolutions is vital for accurate assessment․

Understanding the Test Methods

MIL-STD-810F encompasses diverse tests—low/high temperature, shock, humidity—evaluating product limits; detailed PDF documentation outlines each procedure for comprehensive environmental resilience assessment․

Method 500․5: Low Temperature

Method 500․5 of MIL-STD-810F assesses equipment performance under extremely cold conditions․ The PDF standard details procedures for exposing items to specified low temperatures over a defined duration, simulating operational environments like arctic conditions․ This testing evaluates material properties, functionality, and operational capability at reduced temperatures․

The procedure involves controlled temperature reduction, stabilization periods, and performance checks․ The PDF document outlines specific temperature ranges and durations based on the intended application and operational profile․ Successful completion demonstrates the equipment’s ability to withstand cold storage, transport, and operation without degradation․ Understanding the nuances within the MIL-STD-810F PDF is crucial for accurate interpretation of low-temperature performance claims․

Method 501․5: High Temperature

Method 501․5, detailed within the MIL-STD-810F PDF, evaluates equipment functionality under elevated temperature conditions․ This test simulates exposure to hot environments, assessing material stability, operational performance, and potential degradation․ The PDF specifies precise temperature levels and exposure durations, tailored to the equipment’s intended operational context․

The procedure involves gradually increasing temperature, maintaining it for a set period, and then evaluating performance․ The MIL-STD-810F PDF outlines criteria for assessing functionality, including visual inspection for damage and performance testing․ Passing this test indicates the equipment can reliably operate in hot climates or during periods of high heat generation․ Thorough review of the PDF is essential for understanding the specific parameters and acceptance criteria․

Method 502․5: Temperature Shock

Method 502․5, as comprehensively documented in the MIL-STD-810F PDF, assesses a product’s ability to withstand rapid temperature fluctuations․ This test simulates the stresses caused by abrupt environmental changes, crucial for equipment operating in diverse climates or undergoing frequent temperature cycling․ The PDF details specific temperature ranges, transition rates, and dwell times․

The procedure involves cycling the equipment between high and low temperatures, observing for any physical damage, performance degradation, or functional failures․ The MIL-STD-810F PDF emphasizes evaluating material compatibility and structural integrity․ Successful completion demonstrates resilience against thermal stress, preventing cracks, warping, or operational inconsistencies․ Careful examination of the PDF is vital for correct implementation and interpretation of results․

Method 503․1: Humidity

Method 503․1, thoroughly outlined within the MIL-STD-810F PDF, evaluates a product’s resistance to humid environments․ This testing simulates the corrosive effects of moisture, crucial for equipment deployed in high-humidity regions or exposed to condensation․ The PDF specifies humidity levels, test durations, and temperature controls․

The procedure involves exposing the equipment to elevated humidity levels, monitoring for corrosion, fungal growth, and performance changes․ The MIL-STD-810F PDF details inspection criteria for assessing material degradation and electronic component reliability․ Passing this test indicates the product can maintain functionality and structural integrity in damp conditions․ A detailed review of the PDF ensures accurate test setup and result analysis, validating long-term durability․

Applications of MIL-STD-810F Certification

MIL-STD-810F certification, detailed in its PDF, applies to ruggedized devices like PDAs, military equipment, laptops, and industrial encoding appliances, ensuring durability․

Ruggedized Mobile Devices (PDAs, Smartphones)

MIL-STD-810F certification, as outlined in the standard’s PDF documentation, is frequently sought by manufacturers of ruggedized mobile devices, including PDAs and smartphones․ This certification demonstrates a commitment to creating devices capable of withstanding harsh environmental conditions․ American Industrial Systems, for example, introduced an Ultra Rugged Mobile PDA specifically rated to IP67 dust and waterproof standards, and meeting MIL-810F environmental standards․

The PDF details tests ensuring these devices can operate reliably in challenging scenarios, from extreme temperatures to accidental drops․ For consumers and professionals alike, a MIL-STD-810F rating signifies increased reliability and longevity, particularly in demanding work environments where device failure isn’t an option․ The standard provides a framework for testing and validating the robustness of these essential tools․

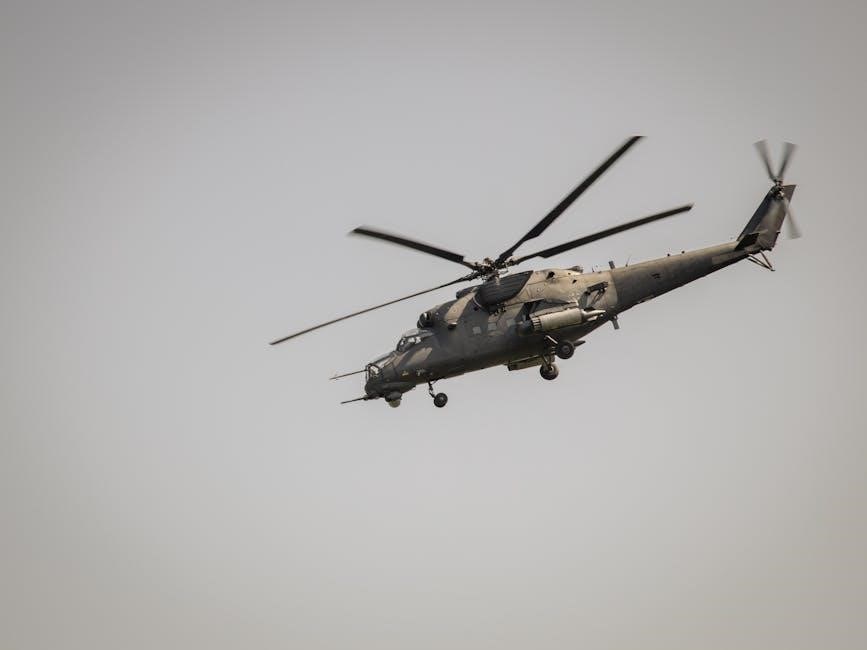

Military and Defense Equipment

The MIL-STD-810F PDF standard is paramount in the development and procurement of military and defense equipment․ VITEC, a leading video solutions provider, highlights this by securing both MIL-STD-810F and MIL-STD-461 certifications for its rugged H․264 encoders; These certifications, detailed within the standard’s documentation, validate the equipment’s ability to function reliably in extreme conditions encountered during military operations․

The PDF outlines rigorous testing procedures for shock, vibration, temperature extremes, and humidity, ensuring equipment can withstand battlefield stresses․ VITEC’s military-grade encoding appliances demonstrate the practical application of the standard, providing robust video capabilities in challenging environments․ Compliance with MIL-STD-810F is often a mandatory requirement for defense contracts, guaranteeing performance and dependability․

Industrial Applications & Encoding Appliances

Beyond military use, the MIL-STD-810F PDF standard proves crucial for industrial applications demanding robust equipment․ VITEC’s rugged H․264 encoders, certified to MIL-STD-810F, exemplify this․ The PDF details tests validating their resilience against shock, vibration, and temperature fluctuations – conditions common in industrial settings․ These encoding appliances deliver reliable video streaming even in harsh environments․

The standard’s documentation ensures consistent performance and longevity, reducing downtime and maintenance costs․ Accessing the MIL-STD-810F PDF allows manufacturers to understand the specific test parameters required for their products․ This is particularly important for encoding appliances used in remote monitoring, surveillance, or critical infrastructure, where reliability is paramount․ The standard’s detailed procedures guarantee a durable and dependable solution․

Laptop and Computer Durability

The MIL-STD-810F PDF standard frequently appears in laptop and computer specifications, signifying enhanced durability․ While not mandatory, manufacturers often cite it to demonstrate a product’s ability to withstand challenging conditions․ The PDF outlines rigorous testing procedures – including temperature extremes, humidity, and shock – designed to simulate real-world usage․

However, it’s crucial to understand that “meeting” MIL-STD-810F doesn’t mean a laptop passed all tests․ Manufacturers select specific tests relevant to their product․ Reviewing the MIL-STD-810F PDF helps consumers decipher these claims․ ADLINK’s VPX6000 blade, for example, is designed to meet the standard for harsh environments, showcasing its robust build․ Understanding the specific tests performed provides a clearer picture of a computer’s true resilience․

Interpreting MIL-STD-810F Compliance Claims

MIL-STD-810F PDF compliance claims, like “meets or exceeds,” require scrutiny; the PDF reveals that specific test procedures are vital for accurate interpretation․

What “Meets or Exceeds” Actually Means

MIL-STD-810F PDF documentation clarifies that “meets or exceeds” is often a marketing term, lacking standardized definition․ It doesn’t necessarily mean a product underwent all MIL-STD-810F tests․ Manufacturers might test against only a subset of relevant procedures, or modify test parameters․

The PDF emphasizes that exceeding the standard implies surpassing specific test criteria, but doesn’t guarantee overall robustness․ A product might excel in temperature resistance (Method 500․5) but falter in humidity (Method 503․1)․

Therefore, relying solely on this phrase is insufficient; detailed test reports, referencing specific MIL-STD-810F methods and results, are crucial for verifying genuine compliance․ The PDF itself is the key to understanding the scope of any claim․

The Importance of Specific Test Procedures

The MIL-STD-810F PDF highlights that the standard isn’t a single test, but a series of individual test methods (like 500․5 for low temperature, 501․5 for high temperature)․ Understanding which procedures a product passed is vital․

Simply stating “MIL-STD-810F certified” is insufficient; knowing if it withstood temperature shock (Method 502․5) or humidity (Method 503․1) reveals its specific strengths․ The PDF details each method’s parameters and expected outcomes․

Different applications demand different resilience․ A ruggedized PDA requires different testing than military defense equipment․ The PDF allows discerning users to assess if the tested procedures align with their intended use, ensuring the certification is relevant and meaningful․

Limitations of Self-Certification

The MIL-STD-810F PDF doesn’t inherently guarantee independent verification․ Many “MIL-STD-810F compliant” claims stem from self-certification – a manufacturer testing their own products․ While not invalid, this lacks the objectivity of an accredited, third-party lab․

The standard allows for interpretation; manufacturers might select tests favorable to their product, omitting more challenging procedures․ The PDF itself doesn’t prevent this selective testing․

Therefore, relying solely on a manufacturer’s claim requires caution․ Seeking evidence of independent lab reports, or verifying certification through official channels, is crucial․ The PDF serves as a reference, but doesn’t automatically validate a product’s true ruggedness․

Accessing MIL-STD-810F Documentation (PDF)

MIL-STD-810F PDF access involves official sources, potentially incurring costs, alongside readily available third-party summaries offering condensed information about the standard․

Official Sources for the Standard

Obtaining the official MIL-STD-810F PDF document typically involves purchasing it directly from authorized sources․ While the standard has been superseded by newer versions, accessing the F revision requires navigating specific channels․ The primary source is often the U․S․ Government Publishing Office (GPO), or through standardization document providers․

However, be aware that these sources generally require a purchase, and the cost can vary․ The price reflects the comprehensive nature of the document, detailing numerous test methods and procedures․ It’s crucial to verify the legitimacy of any vendor claiming to offer the official PDF to avoid counterfeit or outdated versions․ Direct access ensures you have the complete and accurate standard for reference and compliance purposes․

Cost and Availability of the PDF Document

The MIL-STD-810F PDF isn’t freely available; acquiring it necessitates a purchase․ Costs can fluctuate depending on the vendor, but expect to pay several hundred dollars for the complete standard․ Several companies specialize in providing access to military and government specifications, acting as intermediaries․

Availability is generally consistent through these authorized distributors, offering digital downloads of the PDF․ However, given the standard’s age (superseded in 2008), finding a readily available version might require some searching․ Be cautious of significantly discounted offers, as they could indicate unauthorized copies․ Prioritize purchasing from reputable sources to ensure you receive a legitimate and up-to-date document for accurate reference․

Third-Party Resources and Summaries

While the full MIL-STD-810F PDF requires purchase, numerous online resources offer summaries and interpretations of the standard․ These can be valuable for understanding the core test methods and requirements without the expense of the complete document․ Websites dedicated to ruggedized technology and military specifications frequently publish articles and guides explaining key aspects of MIL-STD-810F․

However, it’s crucial to remember that these summaries are not substitutes for the official standard․ They may not cover all nuances or specific test procedures․ Always verify information with the official PDF if precise compliance is needed․ These resources are best used for gaining a general understanding or for preliminary research before investing in the full documentation․

Examples of Products Certified to MIL-STD-810F

MIL-STD-810F certification appears in products like ruggedized iPads, VITEC encoders, UltraCell fuel cells, and ADLINK VPX blades, demonstrating enhanced durability․

Trident Aegis iPad Air Case

The Trident Aegis iPad Air case exemplifies MIL-STD-810F compliance in consumer products․ Despite a cool-sounding name and claims of meeting or exceeding the standard, understanding the specifics of testing is crucial․ The MIL-STD-810F standard outlines a series of environmental tests, but a “meets or exceeds” claim doesn’t detail which tests were performed or to what degree․

Consumers should be aware that self-certification is common, and independent verification is often lacking․ While the Aegis case aims to provide robust protection, the MIL-STD-810F designation alone doesn’t guarantee complete protection against all potential hazards․ Accessing the full MIL-STD-810F PDF documentation would reveal the breadth of tests available, highlighting the importance of specific procedure details․

VITEC Rugged H․264 Encoders

VITEC’s Rugged H․264 Encoders demonstrate MIL-STD-810F and MIL-STD-461 certifications, crucial for military applications․ These certifications signify the encoders’ ability to withstand harsh environmental conditions and electromagnetic interference․ However, simply stating compliance with MIL-STD-810F isn’t enough; understanding the specific tests performed is vital․

Accessing the complete MIL-STD-810F PDF document reveals the extensive range of tests available, from temperature extremes to shock and vibration․ VITEC’s achievement highlights the standard’s importance in ensuring reliable video solutions for defense․ While the encoders meet rigorous standards, detailed test reports are essential for verifying the extent of their ruggedization․ Examining the PDF clarifies what “ruggedized” truly means in this context․

UltraCell Fuel Cell Systems

UltraCell Corporation’s XX25 Reformed Methanol Fuel Cell (RMFC) system successfully passed a series of MIL-STD-810F tests, validating its robustness for mobile power applications․ This certification is significant, as fuel cell systems often operate in demanding environments․ However, the MIL-STD-810F PDF details numerous test methods, and understanding which tests were completed is crucial for assessing the system’s capabilities․

The PDF document clarifies that “meeting” the standard doesn’t imply passing every test․ UltraCell’s success demonstrates the viability of fuel cell technology in rugged settings․ Accessing the standard’s documentation allows for a deeper understanding of the specific shock, vibration, and temperature tests the RMFC endured, confirming its suitability for challenging deployments․

ADLINK VPX6000 VPX Blade

ADLINK Technology’s dual-processor VPX6000 6U VPX blade, featuring quad-core Intel Core i7 processors, is engineered to withstand harsh environments, meeting MIL-STD-810F standards․ This rugged design is critical for applications demanding high performance and reliability in challenging conditions․ However, the full scope of this compliance is detailed within the MIL-STD-810F PDF․

The PDF document outlines specific test procedures, and understanding which tests the VPX6000 passed is vital․ It’s important to note that “meeting” the standard doesn’t equate to passing all tests․ Reviewing the documentation reveals the blade’s resistance to temperature extremes, shock, and vibration, confirming its suitability for demanding military and industrial applications․ Accessing the standard provides transparency regarding the testing process․